Etching is a manufacturing process that removes part of the material from the surface of the material by chemical or physical methods to form a specific pattern or design. The etching process can be achieved by wet etching (using chemical solutions) and dry etching (using plasma or laser). Wet etching involves immersing the material in a chemical solution, while dry etching uses plasma or laser to precisely remove part of the surface of the material.

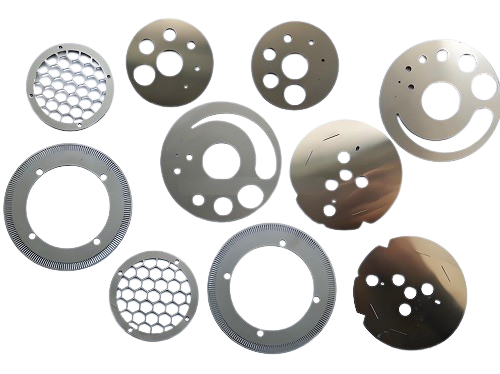

At Turnkey, suitable abrasives can be provided according to the etching target material and requirements, including: steel shot, steel sand, aluminum oxide, glass beads, etc. Turnkey strictly controls the etching process, including the control of chemical parameters (solution concentration, component ratio) and physical parameters (time, temperature, injection pressure). After etching is completed, subsequent treatments such as cleaning, degumming, and polishing are also carried out to ensure the manufacture of high-quality and high-performance products.

Turnkey's etching technology provides high-quality services for semiconductors, consumer electronics, precision machinery, medical equipment, aerospace, and other fields, helping innovation and development in many fields.