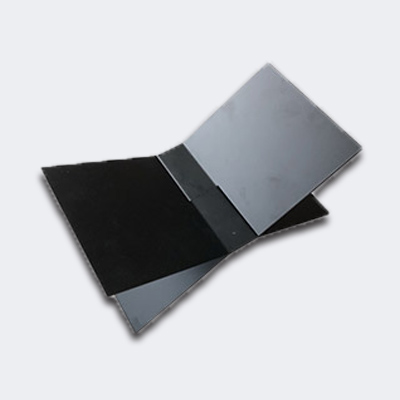

Tailored Excellence in Sheet Metal Fabrication

No MOQ Limited, Factory Direct, Lead Time As Fast As 2 Days - Unleash the Power of Customized Sheet Metal Solutions! Elevate Your Precision Manufacturing Experience with Our Exceptional Services!

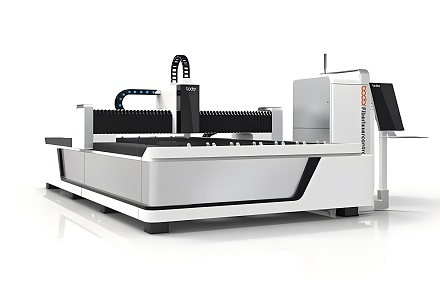

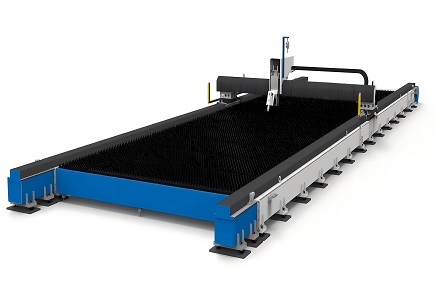

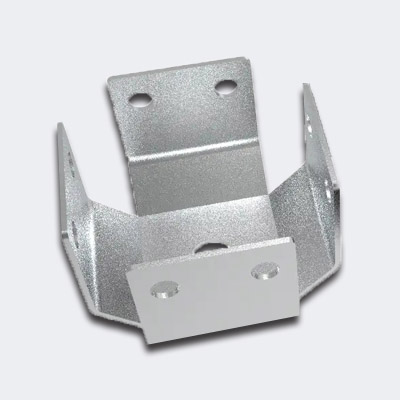

TurnkeyModel focuses on laser cutting and processing and has 15+ sets of advanced equipment, includes: Fiber laser cutting machine: uses fiber laser source to perform high-precision, high-speed cutting, suitable for various metal plates and profiles. CO2 laser cutting machine: uses CO2 laser source for cutting, suitable for different types of metal materials. All-in-one laser cutting machine: an integrated device that integrates a laser cutting system, providing convenient operation and efficient cutting. Feeder: used to feed raw materials into the laser cutting machine to achieve automated production processes. Laser cutting technology plays an important role in sheet metal processing and is mainly used to cut various metal plates and profiles, such as stainless steel, carbon steel, aluminum, etc. Through laser cutting, parts of various complex shapes and smaller sizes can be processed, with the advantages of high processing quality and stability. We are committed to providing efficient and accurate laser cutting processing services to meet our customers' needs for cutting various metal materials.

Prepare the laser cutting machine, check the equipment status and ensure its normal operation

According to the material type, thickness and other parameters, set the corresponding cutting parameters

Place the workpiece to be cut on the workbench of the laser cutting machine

Start the equipment according to the starting process of the laser cutting machine

After setting the cutting parameters on the control panel of the laser cutting machine, press the start button to cut

After cutting, the cutting quality shall be inspected

Call Us:

Email Us:

Opening Hours:

Copyright © 2025 Shenzhen Tengqi Technology Co., Ltd All Rights Reserved