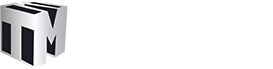

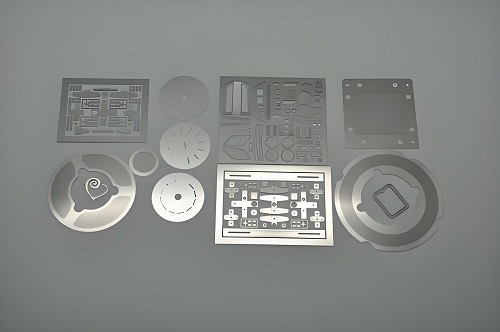

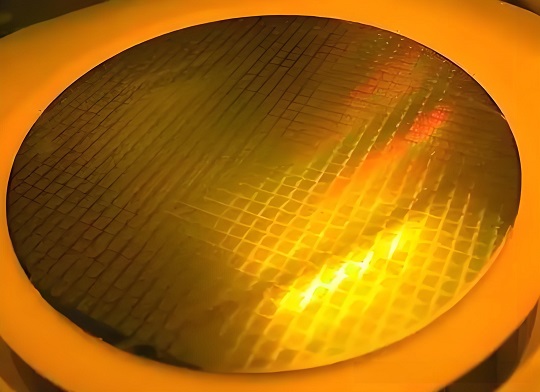

Photolithography technology refers to the technique of transferring patterns from a mask to a substrate using photoresist under the influence of light. The main process is as follows: firstly, ultraviolet light is irradiated through a mask onto the surface of the substrate with a layer of photoresist film attached, causing a chemical reaction in the photoresist in the exposed area; Then, by using development technology to dissolve and remove the photoresist in the exposed or unexposed areas (the former is called positive photoresist, and the latter is called negative photoresist), the pattern on the mask is replicated onto the photoresist film; Finally, the pattern is transferred onto the substrate using etching technology.

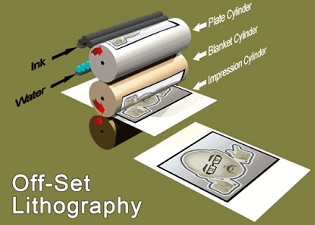

Turnkey service can optimize the surface treatment process of photolithography technology according to the specific needs and process requirements of customers. By adjusting lithography parameters, improving coating techniques, and optimizing the development process, the quality and resolution of lithography imaging can be improved while reducing production costs.

Turnkey services can significantly increase the surface treatment capacity of photolithography technology by optimizing production line layout, improving equipment utilization and automation level. This helps customers produce more high-quality products in a short period of time to meet market demand.

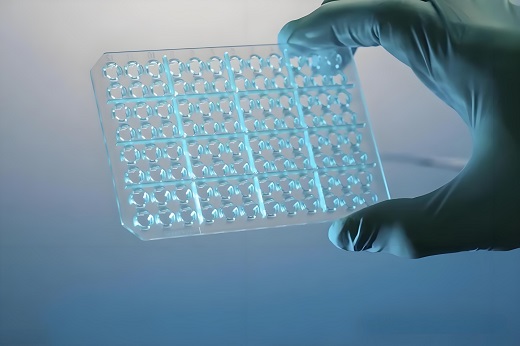

Turnkey services can provide customized solutions based on specific customer needs. This customized service not only meets the personalized needs of customers, but also enhances their dependence and loyalty to the service provider.

Turnkey service providers have established long-term and stable cooperative relationships with customers. This cooperative relationship helps both parties to jointly respond to market changes and technological challenges, achieving mutual benefit and win-win results.