Sheet Metal Fabrication is an industry that involves transforming metal sheets (such as steel, aluminum, stainless steel, etc.) into products of the desired shape and size through a series of manufacturing processes. The following is a detailed analysis of the field:

1、 Definition and Overview

Metal sheet manufacturing is a comprehensive process that includes design, cutting, bending, welding, surface treatment, and other steps, aimed at transforming raw metal sheets into finished products that meet specific application requirements. These finished products are widely used in various fields such as automobiles, aerospace, construction, electronic equipment, medical equipment, etc.

2、 Main technological processes

Design: Based on product requirements and specifications, carry out drawing design and process planning. This includes determining the material, thickness, size, as well as the required shape and features of the metal plate.

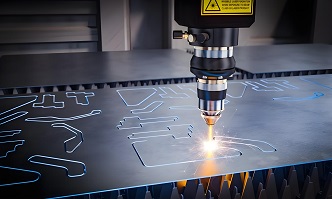

Cutting: Using methods such as Laser Cutting, water cutting, plasma cutting, or mechanical cutting to cut metal plates into the desired shape and size. The cutting process requires precise control to ensure the quality and accuracy of the product.

Bending and Forming: By stamping, bending, stretching and other processes, the cut metal plate is processed into the desired shape. These manufacturing processes require high-precision molds and equipment to ensure that the shape and size of the product meet the design requirements.

Welding and assembly: Assemble multiple metal components together through welding, riveting, or bolted connections to form a complete product. The welding process requires strict control of welding parameters to ensure the quality and strength of the weld seam.

Surface treatment: Sandblasting, spraying, electroplating and other surface treatments are carried out on metal plates to improve the corrosion resistance, aesthetics and service life of the product.

3、 Material selection

The commonly used materials in metal sheet manufacturing include steel, aluminum, stainless steel, copper, etc. The selection of these materials depends on the application requirements, cost budget, and processing performance of the product. For example, steel has high strength and rigidity, making it suitable for applications that require heavy loads and impacts; Aluminum has the characteristics of lightweight, corrosion resistance, and easy processing, and is suitable for fields such as aerospace and electronic equipment.

4、 Application Fields

Products manufactured from metal sheet metal are widely used in multiple fields, including:

Automobile manufacturing: Metal sheet parts used for manufacturing body, chassis, engine and other components.

Aerospace: Used for manufacturing shells, structural components, etc. of aircraft, rockets, and other aerospace vehicles.

Architecture: Metal panels used to manufacture building components such as roofs, walls, doors, and windows.

Electronic equipment: Metal sheet parts used to manufacture electronic devices such as chassis and heat sinks.

Medical equipment: used for manufacturing metal components such as surgical instruments and medical devices.

5、 Development Trends and Challenges

Development trend:

Technological innovation: With the development of automation and intelligent technology, the metal sheet manufacturing industry will pay more attention to technological innovation and process improvement to improve production efficiency and product quality.

Green environmental protection: The increasing awareness of environmental protection has prompted the metal sheet manufacturing industry to pay more attention to green production and sustainable development. Adopting environmentally friendly materials and processes to reduce the discharge of waste and pollutants.

Customized services: With the diversification of market demand, the metal sheet manufacturing industry will pay more attention to providing customized services to meet customers' personalized needs.

Challenge:

Market competition intensifies: With the continuous development of the metal sheet manufacturing industry, market competition is becoming increasingly fierce. Enterprises need to continuously improve their competitiveness to cope with market challenges.

Rising raw material costs: The price fluctuations of metal raw materials have an impact on the cost of the metal sheet manufacturing industry. Enterprises need to closely monitor market trends and reasonably control raw material costs.

Environmental regulations restrictions: With the increasingly strict environmental regulations, the metal sheet manufacturing industry needs to pay more attention to environmental protection and sustainable development. Enterprises need to increase investment in environmental protection and improve production processes to reduce pollution to the environment.