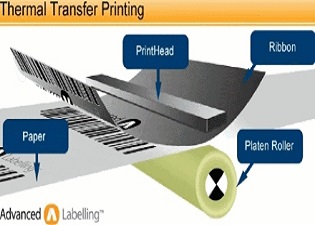

The transfer printing process uses a heat transfer machine to transfer the exquisite patterns on the transfer film onto the surface of the product in one go (heating and pressure). After forming, the ink layer integrates with the surface of the product, creating a realistic and beautiful image, greatly improving the product's grade. However, due to the high technological content of this process, many materials need to be imported.

The Turnkey model provides one-stop service from design to finished product, eliminating the need for customers to communicate with multiple suppliers and simplifying the procurement process.

The supplier is responsible for the entire surface treatment process of heat transfer printing, including material selection, design optimization, printing, and post-processing, to ensure the quality and consistency of the final product.

Turnkey has extensive experience and professional knowledge in heat transfer printing surface treatment, and can provide customers with best practice advice.

They understand the characteristics and printing requirements of different materials, and can ensure that the printing effect meets the customer's expectations.

Turnkey helps customers better control costs as suppliers typically offer more cost-effective solutions.

Through centralized procurement and large-scale production, suppliers can reduce material and production costs, thereby saving costs for customers.